MANUFACTURING

Various mistakes that do not require vocational expertise but are based on human factors are made in production facilities. Even the slightest mistake can cause production processes to be interrupted. Most of these types of mistakes can be prevented by training employees.

Manufacturing requires a cautious balancing between efficiency and protection, which necessitates plant worker preparation. Managers must conduct the workforce efficiently in order to maintain productivity and quality while still meeting deadlines and profitability targets.

VR Trainings offer mental repetitions away from the line to help production associates learn the skills they need to perform their work while still improving situational perception and safety protocol experience. Manufacturers are moving to virtual reality training because it has been shown to cut training time, defect rates, and staff turnover time.

ASSEMBLY TRAINER

Assembly duties consist of repetitive tasks. And, it has one right way of doing it mostly. When the addition of new equipment on the line or onboarding happens, it is important that employees do these tasks in the correct order. A VR assembly trainer reduces the training costs, focuses on the patterns that matter, increases operational efficiency and makes it possible to determine how much time an employee spent on the steps. Teaching the desired torque value is a prominent objective of assembly trainer.

PROCEDURAL KNOWLEDGE

Procedural Knowledge refers to the knowledge of how to perform a specific skill or task, and is considered knowledge related to methods, procedures, or operation of equipment. And each step in the production process has its own procedures. It is vital that these rules, which take place in a wide range from hazard identification to lean manufacturing applications, be understood by the unit employees, and the root causes are comprehended. VR education solutions are preferred to raise this awareness.

QUALITY

Quality assurance, of course, is an indispensable part of manufacturing. The workforce on this step is needed to be trained and examined. The best-fitting technology for such training and examination is virtual reality. Virtual reality gets a higher rate of comprehension while increasing operational efficiency.

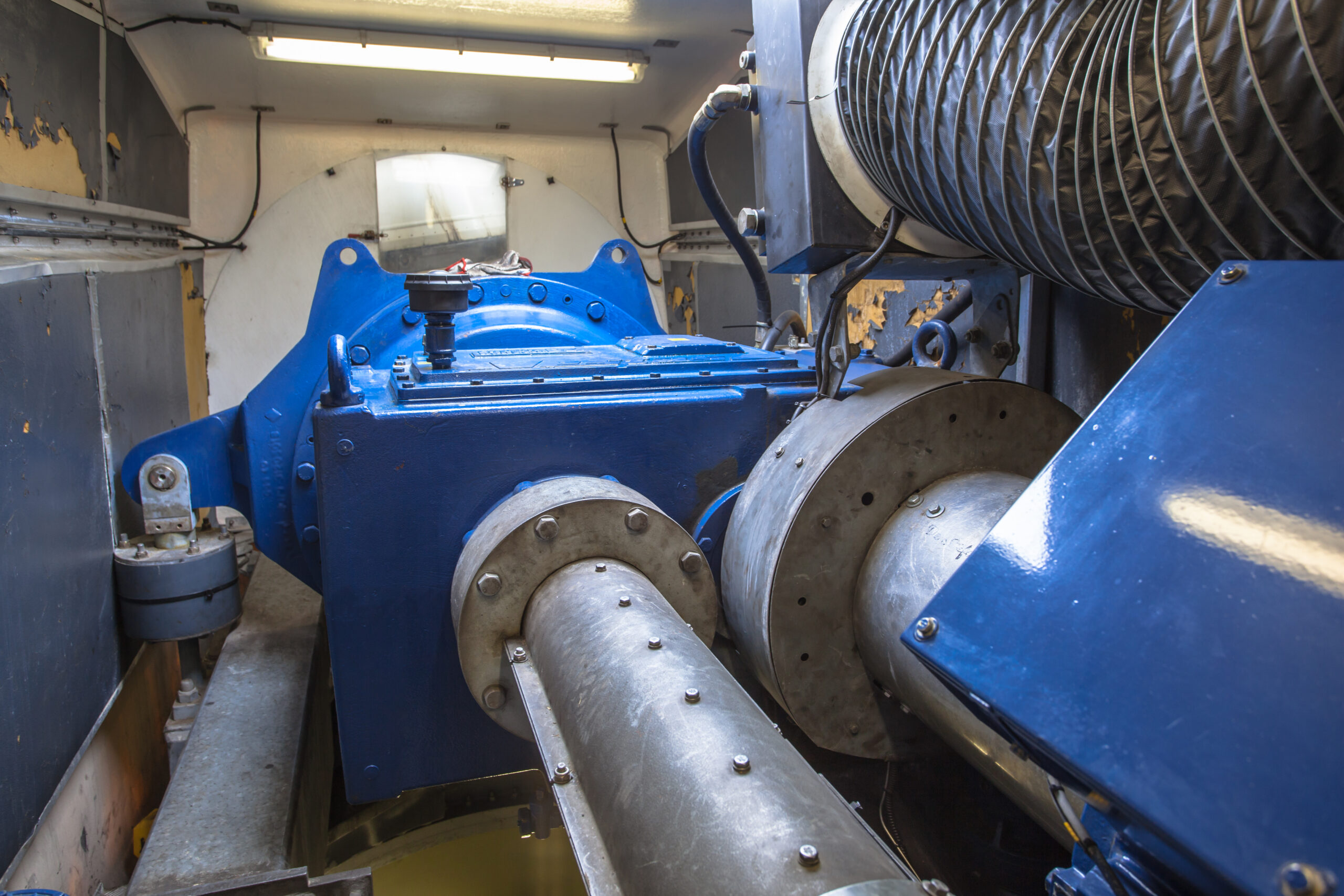

MUSCLE MEMORY

The main difference that distinguishes this solution from the assembly solution is the ability to use machines and equipments. It is important for an operator to not only know the effects of the controls on the machine he uses but also to have the correct reflexes. And the ideal solution for this is Virtual Reality. Because it creates a virtual replica of the machine. Thus, it enables both perceptual memory and muscle memory to be improved.